Design optimization

This section guides you through the process of optimizing the design of axial turbines using TurboFlow. You will learn how to define optimization objectives, set constraints, and utilize the optimization algorithm to achieve the best design. Design optimization is excecuted in two steps:

Load configuration file.

Compute optimal turbine.

Illustrated by a code example:

import os

import turboflow as tf

CONFIG_FILE = os.path.abspath("my_configuration.yaml") # Get absolute path of configuration file

config = tf.load_config(CONFIG_FILE) # Load configuration file

solver = tf.compute_optimal_turbine(config, export_results=True) # Compute optimal turbine

This page describes the main functionalities and options available when designing turbines using turboflow:

Configuration setup

The configuration must be setup in a yaml file, where certain sections are required, while others are optional, meaning that a default value is provided. In the example below, the full configuration for design optimization is provided, where the required parts are marked with # required and the optional parts are marked with # optional.

In summary, these section are required:

turbomachinery : specifies the turbomachinery configuration.

operation_points: specifies the design point. If a list is provided, the first point is used.

The remaining input is optional. Here is an example of how the configuration file could look for a one-stage axial turbine:

turbomachinery: axial_turbine # Required

operation_points: # Required

fluid_name: air # Required

T0_in: 295.6 # Required

p0_in: 13.8e4 # Required

p_out : 13.8e4/2.298 # Required

omega: 1627 # Required

alpha_in: 0 # Required

simulation_options: # Optional

deviation_model : aungier # Optional

choking_criterion : critical_mach_number # Optional

rel_step_fd: 1e-4 # Optional

loss_model: # Optional

model: benner # Optional

loss_coefficient: stagnation_pressure # Optional

inlet_displacement_thickness_height_ratio: 0.011 # Optional

tuning_factors: # Optional

profile: 1.00 # Optional

incidence: 1.00 # Optional

secondary: 1.00 # Optional

trailing: 1.00 # Optional

clearance: 1.00 # Optional

design_optimization: # Optional

objective_function: # Optional

variable : overall.efficiency_ts # Optional

scale : 10 # Optional

type : maximize # Optional

variables : # Optional

specific_speed : # Optional

value : 1.2

lower_bound : 0.01

upper_bound : 10

blade_jet_ratio : # Optional

value : 0.5

lower_bound : 0.1

upper_bound : 0.9

hub_tip_ratio_in : # Optional

value : [0.6, 0.6]

lower_bound : [0.6, 0.6]

upper_bound : [0.9, 0.9]

hub_tip_ratio_out : # Optional

value : [0.6, 0.6]

lower_bound : [0.6, 0.6]

upper_bound : [0.9, 0.9]

aspect_ratio : # Optional

value : [1.5, 1.5]

lower_bound : [1.0, 1.0]

upper_bound : [2.0, 2.0]

pitch_chord_ratio : # Optional

value : [0.9, 0.9]

lower_bound : [0.75, 0.75]

upper_bound : [1.10, 1.10]

trailing_edge_thickness_opening_ratio : # Optional

value : [0.1, 0.1]

lower_bound : [0.05, 0.05]

upper_bound : [0.4, 0.4]

leading_edge_angle : # Optional

value : [0.41, 0.5]

lower_bound : [0.41, 0.08]

upper_bound : [0.92, 0.58]

gauging_angle : # Optional

value : [0.17, 0.94]

lower_bound : [0.06, 0.72]

upper_bound : [0.28, 0.94]

v_in : # Optional

value : 0.1

lower_bound : 0.001

upper_bound : 0.5

w_out : # Optional

value : [0.65, 0.65]

lower_bound : [0.1, 0.1]

upper_bound : [1.0, 1.0]

s_out : # Optional

value : [0.15, 0.15]

lower_bound : [0.0, 0.0]

upper_bound : [0.32, 0.32]

beta_out : # Optional

value : [0.83, 0.17]

lower_bound : [0.72, 0.06]

upper_bound : [0.94, 0.28]

v_crit_in : # Optional

value : [0.4, 0.4]

lower_bound : [0.1, 0.1]

upper_bound : [1.0, 1.0]

beta_crit_throat : # Optional

value : [0.83, 0.17]

lower_bound : [0.72, 0.06]

upper_bound : [0.94, 0.28]

w_crit_throat : # Optional

value : [0.65, 0.65]

lower_bound : [0.1, 0.1]

upper_bound : [1.0, 1.0]

s_crit_throat : # Optional

value : [0.15, 0.15]

lower_bound : [0.0, 0.0]

upper_bound : [0.32, 0.32]

throat_location_fraction : # Optional

value : [1.0, 1.0]

leading_edge_diameter :

value : [2*0.127e-2, 2*0.081e-2]

leading_edge_wedge_angle : # Optional

value : [50.0, 50.0]

tip_clearance : # Optional

value : [0.00, 0.030e-2]

cascade_type : # Optional

value : ["stator", "rotor"]

constraints : # Optional

- variable : overall.mass_flow_rate # Optional

type : "="

value : 2.5

normalize : True

- variable : additional_constraints.interspace_area_ratio # Optional

type : "="

value : 1

normalize : True

radius_type : "constant_mean" # Optional

solver_options: # Optional

library: scipy # Optional

method: slsqp # Optional

derivative_method: 2-point # Optional

derivative_abs_step: 1e-6 # Optional

print_convergence: True # Optional

plot_convergence: True # Optional

update_on: "gradient" # Optional

options : # Optional

tol: 1e-3 # Optional

max_iter: 100 # Optional

The design_optimization section contains information on the objective function, constraints and design variables:

objective_function: defined by specifying variable, type and scale.

constraints: each constraint is defined by specifying the variable name, type, value and if the constraint should be normalized or not.

variables: set of variables required for design optimization. The variable is considered a design variable if bounds are provided. All variables have a default value, and some have defualt bounds. Note that velocities (v and w), entropies (s) and flow angles (beta) must be design variables.

See Configuration Options for more information regarding the available inputs.

To load the configuration file, the absolute path must be provided to turboflow.load_config:

import os

import turboflow as tf

CONFIG_FILE = os.path.abspath("my_configuration.yaml") # Get absolute path of the configuration file

config = tf.load_config(CONFIG_FILE) # Load configuration file

Note

The only current available option for turbomachinery is axial_turbine.

Note

Velocities (v and w), entropies (s) and flow angles (beta) in the variables section must be provided with bounds (as design variables).

Compute optimal turbine

To compute the optimal turbine, simply provide the configuration file to the function compute_optimal_turbine:

import os

import turboflow as tf

CONFIG_FILE = os.path.abspath("my_configuration.yaml") # Get absolute path of the configuration file

config = tf.load_config(CONFIG_FILE) # Load configuration file

solver = tf.compute_optimal_turbine(

out_filename=None,

out_dir="output",

export_results=True,

)

If export_results is set to True, the simulation data is exported as an Excel file. The file is saved either to a specified directory (out_dir) or to the default directory “output”. The default filename (out_filename) is design_optimization_{current_time}, where current_time is a string formatted as {year}{month}{day}{hour}{minute}_{second}.

Plotting results

Plotting functions are provided to graphically illustrate the simulated data:

Plot velocity triangles: turboflow.plot_velocity_triangles

Plot axial-radial plane: turboflow.plot_axial_radial_plane

Plot axial-tangential plane: turboflow.plot_view_axial_tangential

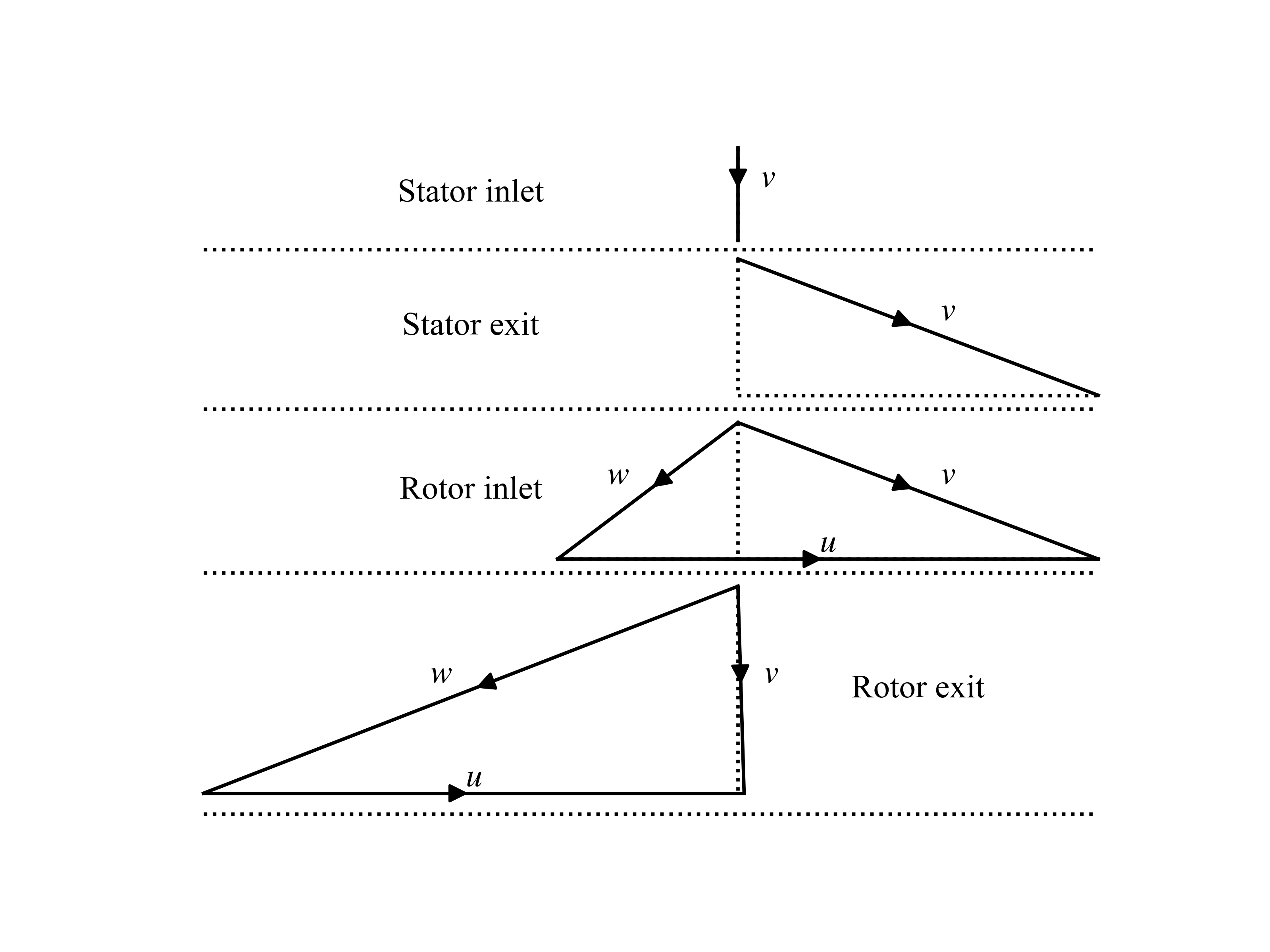

Plot velocity triangles

This function plots the velocity triangles at each plane of the axial turbine. The plot is initialized by providing the plane specific data from the solution of optimization problem:

import os

import turboflow as tf

CONFIG_FILE = os.path.abspath("my_configuration.yaml") # Get absolute path of the configuration file

config = tf.load_config(CONFIG_FILE) # Load configuration file

solver = tf.compute_optimal_turbine(

out_filename=None,

out_dir="output",

export_results=True,

)

fig, ax = tf.plot_functions.plot_velocity_triangles_planes(solver.problem.results["plane"])

Here is an example of how the velocity triangle plots looks:

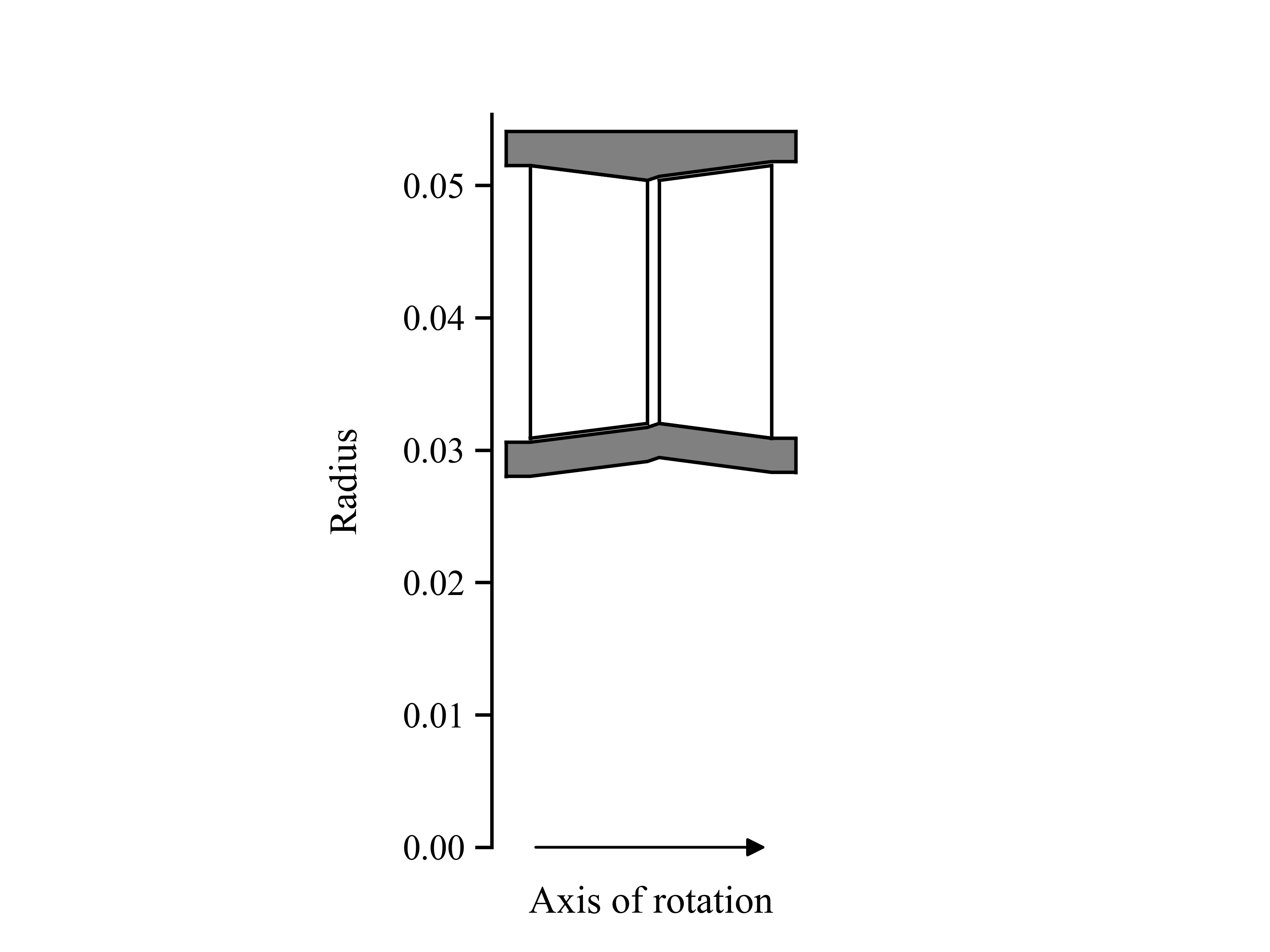

Plot axial-radial plane

This function plots the geometry of an axial-turbine in the axial-radial plane. The plot is initialized by providing the geometry from the solution of the optimization problem:

import os

import turboflow as tf

CONFIG_FILE = os.path.abspath("my_configuration.yaml") # Get absolute path of the configuration file

config = tf.load_config(CONFIG_FILE) # Load configuration file

solver = tf.compute_optimal_turbine(

out_filename=None,

out_dir="output",

export_results=True,

)

fig, ax = tf.plot_functions.plot_axial_radial_plane(solver.problem.geometry)

Here is an example of how the plot look:

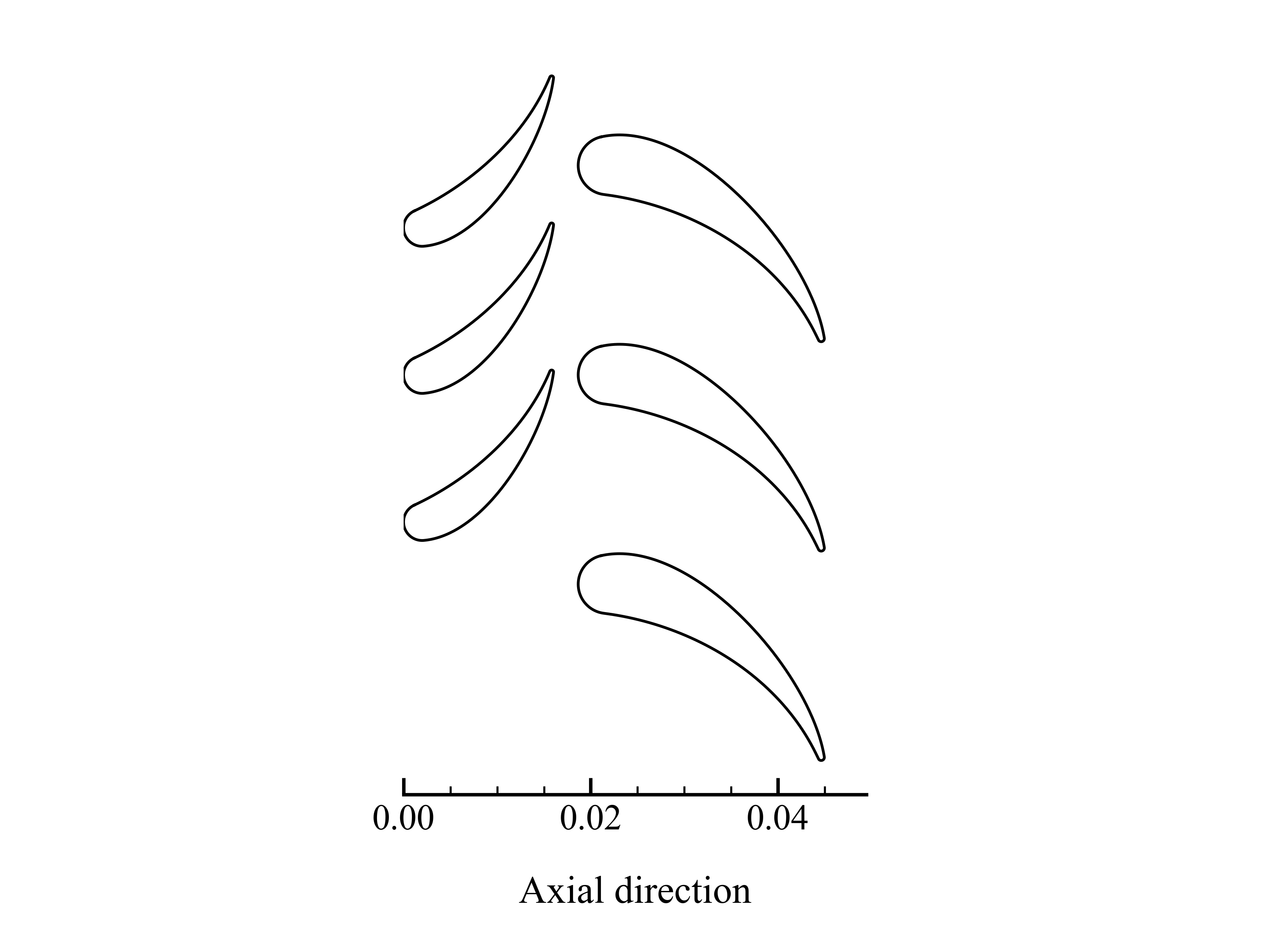

Plot axial-tangential plane

This function plots the geometry of an axial-turbine in the axial-tangential plane. The plot is initialized by providing a solver object:

import os

import turboflow as tf

CONFIG_FILE = os.path.abspath("my_configuration.yaml") # Get absolute path of the configuration file

config = tf.load_config(CONFIG_FILE) # Load configuration file

solver = tf.compute_optimal_turbine(

out_filename=None,

out_dir="output",

export_results=True,

)

# Plot geometry in the axial-tangential plane

fig, ax = tf.plot_functions.plot_view_axial_tangential(solver.problem)

Here is an example of how the plot look: